The wire rope pressing machine is a specialized hydraulic press designed for crimping aluminum or steel ferrules onto wire ropes. It ensures strong, safe, and reliable terminations for lifting, rigging, marine, and construction applications. With advanced hydraulic power and precision-engineered molds, the machine delivers consistent performance and high efficiency in wire rope assembly.

▲ Wire rope pressing machine CLH series new product. The aluminum metal alloy inhibits to spread extensively among nations, making manufacturing size accurate, the structure is simple and direct.

▲CLH series pressing machine is we combine with market condition, the independence develops the new model of production, the machine’s craft technique is more perfect, structure reasonable, hard enduring, operate a humanization, extensively applied in each big mineral mountain, metallurgy, power station, petroleum, port etc.

Specification

Applications

The primary function of this machine is to create end terminations on wire rope. These terminations are then used to connect the rope to other components. Key applications include:

-

Lifting & Hoisting: Creating loops (eyes) for hooks, shackles, and links on slings and crane cables.

-

Rigging: Securing cables in construction, theater rigging, and shipbuilding.

-

Mining: Assembling heavy-duty cables for elevators, conveyors, and haulage systems.

-

Transportation: Manufacturing and repairing cables for elevators, ski lifts, gondolas, and suspension bridges.

-

Agriculture & Forestry: Repairing and assembling cables for winches and heavy equipment.

-

General Industry: Any application where a reliable, non-slip wire rope end is required.

How Does It Work?

The process is based on the principle of cold forming using hydraulic power.

-

Preparation: A metal socket (a open or closed spelter socket, ferrule, or loop sleeve) is placed over the end of the wire rope. The rope is inserted into the socket, often after forming an eye.

-

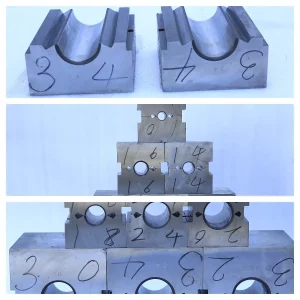

Positioning: The socket and rope are placed into the die cavity of the swaging machine. The dies are shaped to match the final, compressed form of the socket (typically hexagonal or oval).

-

Application of Force: The operator activates the hydraulic pump (manually, electrically, or with air). The pump forces hydraulic fluid into a cylinder, which drives a piston.

-

Swaging (Compression): The piston's force is transferred to the dies, which close with immense pressure (often measured in tons), uniformly compressing the metal socket around the wire rope strands.

-

Release and Completion: The hydraulic pressure is released, the dies open, and the completed assembly is removed. The socket is now permanently deformed and bonded to the wire rope, forming a connection that is often stronger than the rope itself.

Product Details