Hand Pallet Truck 5000 – Heavy-Duty Material Handling Solution

The Hand Pallet Truck 5000 is designed for efficient, safe, and effortless material handling in warehouses, factories, retail stores, and logistics centers. Built with a robust steel frame and precision hydraulic pump, this pallet truck delivers outstanding durability and performance for daily operations.

1. Forks are divided into 550mm and 685mm.

2. Human body engineering design handle, simple three-step control.

3. Highly balanced reinforced frame.

4. The push rod under the fork can be manually adjusted to control the lower height of the fork.

5. All specifications are equipped with training wheels to ensure stability and safety when transporting goods on slopes.

6. Bearing wheels are all double wheels, which can be divided into polyurethane wheels, nylon wheels and steel wheels according to different ground conditions.

Polyurethane wheel suction and punching, shock absorption, wear resistance, mute, suitable for epoxy floor, marble floor, oil floor.

Nylon wheel rotation resistance is the lowest, stable chemical properties, no indentation suitable for cement floor and some more complex road surface.

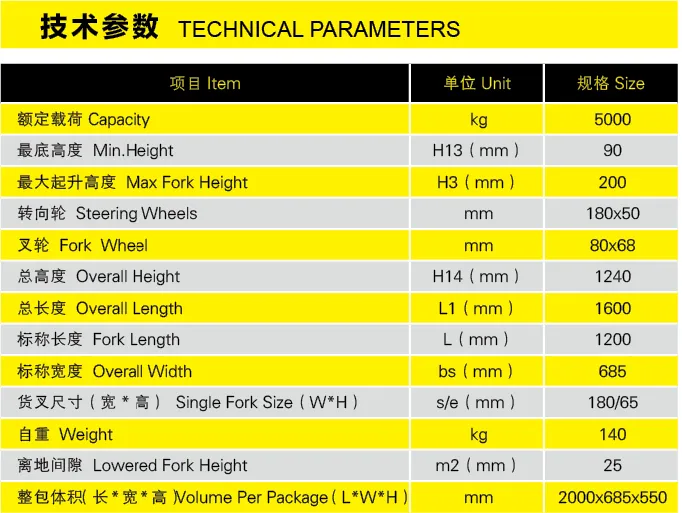

Specification

Product Details

Applications

Hand pallet trucks are the workhorses of short-distance, horizontal transport. Key applications include:

-

Loading and Unloading: Moving pallets from a truck at a loading dock to a staging area inside a facility.

-

Warehouse Operations: Transporting goods between storage racks, to packing stations, or to shipping areas.

-

Retail Stores: Restocking sales floors from backroom storage.

-

Manufacturing: Moving raw materials or finished products between production lines.

-

Inventory Management: Rearranging and organizing pallets within a storage area.

The Principle of Operation

The operation is purely mechanical and hydraulic, requiring no electrical power.

-

Positioning: The operator pushes the control lever down to its lowest position. This lowers the twin "forks" (also called prongs or tines) so they can be slid into the openings of a pallet.

-

Pumping: Once the forks are fully inserted, the operator pumps the handle up and down. This action engages a hydraulic piston inside the main body, raising the forks and lifting the pallet a few inches off the ground (typically 3-4 inches or 85 mm). This small lift is enough to move the load freely.

-

Moving/Traveling: With the load lifted, the operator uses the handle to pull, push, and steer the truck to its desired location. The steering is achieved by the entire hydraulic assembly pivoting on a central pivot point.

-

Lowering: Upon reaching the destination, the operator slowly releases the hydraulic pressure by turning a release valve (usually a lever or knob on the handle). This gently lowers the forks and the pallet to the ground. The truck can then be withdrawn from the pallet.