El levantamiento seguro comienza aquí: How to Use Web Slings Correctly

octubre 10, 2025

LDR Rigging’s Essential Guide to Preventing Costly Mistakes with Synthetic Web Slings

In modern lifting operations, web slings have become one of the most essential and versatile tools for handling heavy loads. Their lightweight, flexibility, and surface protection make them ideal for industries such as construction, logística, envío, and manufacturing.

However, even the strongest web sling can fail if used incorrectly. To ensure safety and efficiency, operators must understand proper usage methods and inspection requirements.

“The key to safe lifting is not just having the right equipment, but knowing how to use it properly,” said the director from Baoding Ldr Rigging Manufacturing Co., Limitado. “Every LDR web sling is tested for quality and strength, but user awareness is equally important.”

🔹 How to Use Web Slings Properly

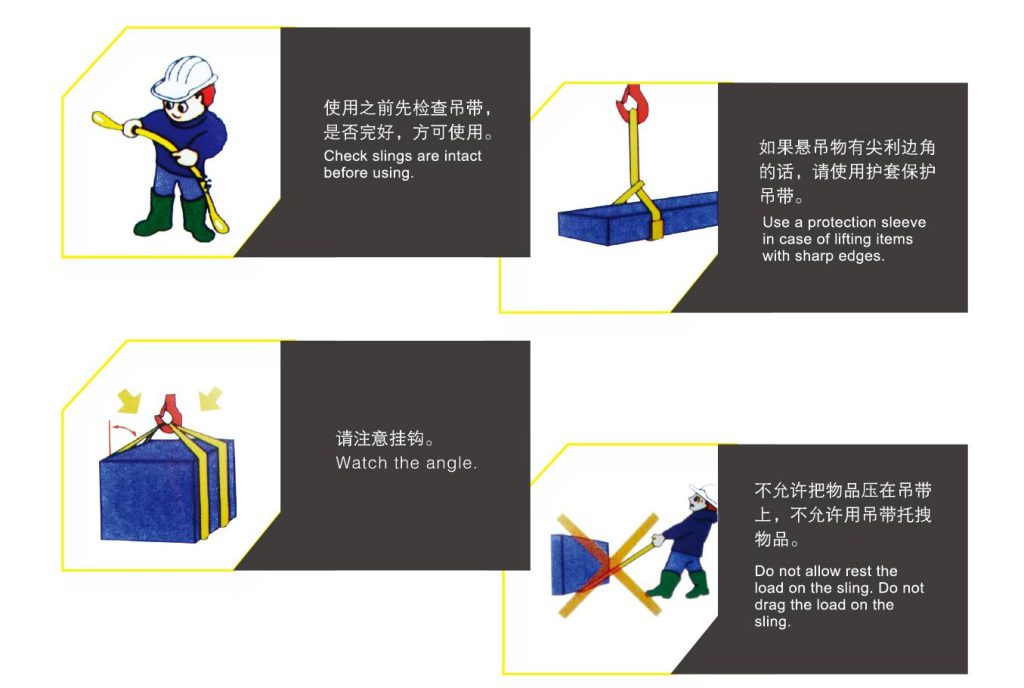

- Inspect Before Every Use

- Check the sling for cuts, abrasions, frayed edges, or chemical damage.

- Make sure identification tags and load capacity markings are clear and legible.

- Select the Right Sling Type

- Choose flat webbing slings, endless slings, or eye & eye slings based on the lifting application.

- Always consider load weight, angle, and surface contact before operation.

- Apply Correct Lifting Angles

- The lifting angle greatly affects load capacity.

- Keep the angle between slings wide enough to balance the load, avoiding excessive tension on the fabric.

- Use Proper Protection

- Place corner protectors or sleeves on sharp edges to prevent cuts.

- Avoid twisting, knotting, or dragging the sling on rough surfaces.

- Store and Maintain Carefully

- After use, clean and dry the sling before storage.

- Keep it away from direct sunlight, chemicals, and high temperatures to extend service life.

⚠️ Safety Warnings and Common Mistakes to Avoid

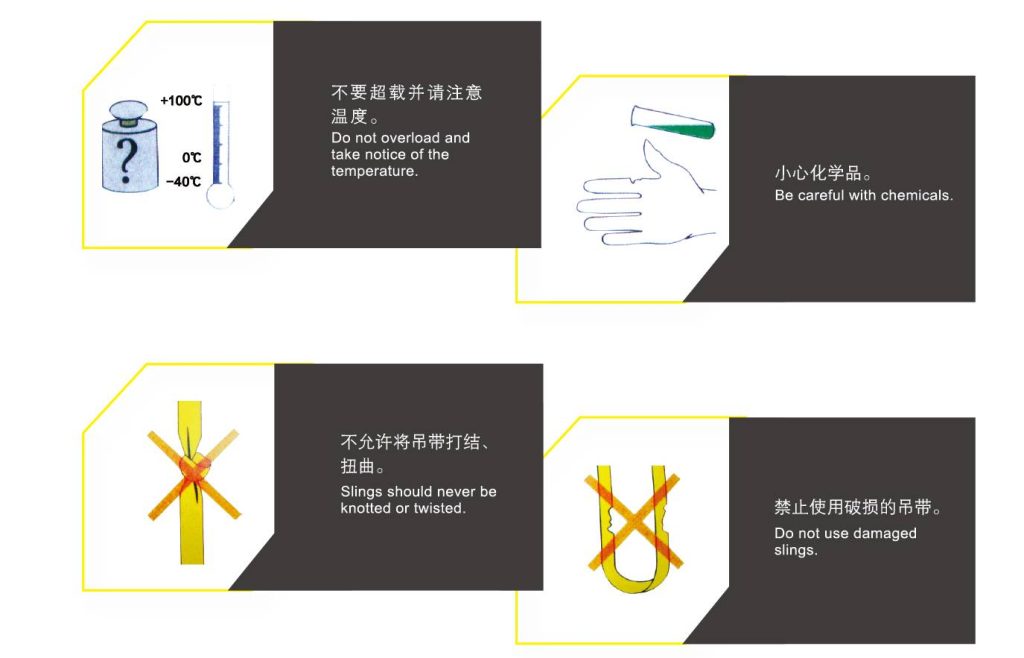

- ❌ Do not exceed the Working Load Limit (WLL) shown on the tag. If several slings are used at the same time, the load should be distributed as evenly as possible among them.

- ❌ Never use damaged or modified slings.

- ❌ Do not connect the soft loops to any device that may cause damage to them. The hanging devices connected to the soft loops should be smooth, without any sharp edges, and their size and shape should not tear the stitched parts of the slings.

- ❌ Avoid contact with sharp edges without protective sleeves.

- ❌ Do not drag when moving the slings and goods.

- ❌ Do not knot or twist the slings, and do not allow the slings to suspend goods for too long.

- ❌ When goods are resting on the slings, do not pull the slings out from under the load.

- ❌ If slings are used in abnormal environments such as high-temperature occasions or for lifting chemical substances, they should be used in accordance with the manufacturer’s instructions and recommendations.

- ❌ If the slings get dirty or are used in an environment with acidic or alkaline tendencies, they should be rinsed immediately with cold water.

- ❌ Slings should be stored in a dark place without ultraviolet radiation, and should not be stored near open flames or other heat sources.

Remember: Proper lifting practices prevent accidents, reduce costs, and protect both workers and equipment.

Web Sling Discard Criteria

A web sling should be immediately removed from service if any of the following conditions are found during inspection or use:

- The webbing (including protective sleeves) shows severe wear, perforation, cuts, or tears.

- The load-bearing seams are open or the stitching is broken or worn out.

- The sling fibers have become softened, aged, less elastic, or weakened in strength.

- The fiber surface appears rough, brittle, or flakes easily.

- The sling has developed hard knots or permanent twists.

- The sling surface shows excessive loosened threads, corrosion, acid or alkali burns, heat fusion, or scorching.

- For slings with red warning lines, the warning line is exposed, indicating that the sling has reached its wear limit.

🌍 About LDR Rigging

Baoding Ldr Rigging Manufacturing Co., Limitado. is a professional manufacturer of lifting and securing products, incluido Eslingas Web, Round Slings, Chain Hoists, Polipastos de palanca, Ratchet Tie Downs, Hardware de aparejo and Material Handing equipment etc.

Every LDR web sling is manufactured from high-tensile polyester, tested to ISO and CE standards, and engineered for durability, flexibility, y seguridad.

For detailed specifications and product options, contact 👉 joy@ldrsling.com.