Estándar de eslinga de correas EN1492 explicado para los compradores

enero 16, 2026

Explicación del estándar de eslinga de correas EN1492: What Buyers Must Know

Introduction

When sourcing lifting slings for industrial applications, safety and compliance are non-negotiable.

For buyers in Europe and many international markets, EN1492 is the most important standard governing synthetic lifting slings, incluido webbing slings and eslingas redondas.

Understanding EN1492 helps buyers ensure safe lifting operations, meet regulatory requirements, and avoid costly compliance risks. This article explains what EN1492 is, how it works, and what buyers must check before placing an order.

What Is the EN1492 Standard?

EN1492 is a European standard that defines the safety requirements, testing methods, and marking rules for synthetic lifting slings.

It applies to:

- Flat webbing slings

- Endless round slings made from synthetic fibers such as polyester, polyamide, and polypropylene.

EN1492 ensures that lifting slings:

- Have sufficient safety margins

- Are clearly identified and traceable

- Perform reliably under rated working loads

For many industrial and construction projects, EN1492 compliance is a mandatory requirement.

EN1492-1 vs EN1492-2: What’s the Difference?

EN1492-1 – Webbing Slings

EN1492-1 applies to flat webbing slings, incluido eye-and-eye and endless configurations.

Key requirements include:

- Minimum safety factor of 7:1

- Color-coded identification

- Clear marking of working load limits

EN1492-2 – Round Slings

EN1492-2 applies to endless round slings with load-bearing yarns enclosed in a protective sleeve.

Key requirements include:

- Standardized color coding

- Internal yarn strength verification

- Durability and wear resistance testing

👉 Buyers should always confirm which part of EN1492 applies to the sling type they are purchasing.

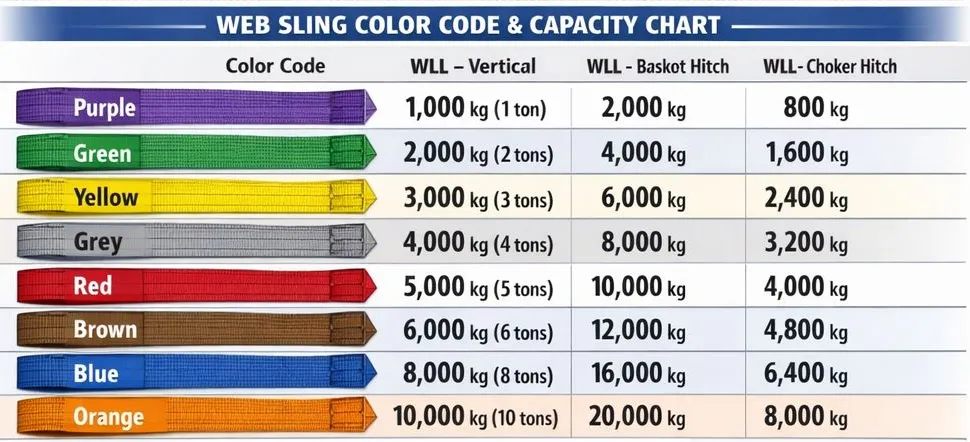

Color Coding and Working Load Limit (WLL)

EN1492 uses standardized color coding to identify sling capacity for straight lifts:

⚠️ Note: Actual WLL depends on the lifting method (straight, choke, basket).

Buyers should always verify the load chart provided by the manufacturer.

Safety Factor Explained (Why 7:1 Matters)

EN1492 requires a minimum safety factor of 7:1, meaning:

- The breaking load must be at least 7 times the rated working load.

- This margin ensures:

- Resistance to wear and aging

- Protection against shock loads

- Safe operation in real-world industrial conditions

For buyers, a 7:1 safety factor is a key indicator of quality and reliability.

EN1492 Marking & Label Requirements

Every EN1492-compliant sling must include a durable identification label showing:

- Manufacturer’s name or trademark

- Working Load Limit (WLL)

- Material type

- Standard reference (EN1492-1 or EN1492-2)

- Manufacturing date or batch number

❗ Missing or unreadable labels are a common reason for sling rejection during inspections.

EN1492 vs ASME: What Buyers Should Know

| Aspect | EN1492 | ASME B30 |

|---|---|---|

| Primary market | Europe | USA |

| Safety factor | 7:1 | Typically 5:1 |

| Color coding | Mandatory | Not standardized |

| Label format | Strict | More flexible |

👉 Buyers supplying multinational projects should confirm which standard is required before ordering.

Common Buyer Mistakes When Sourcing EN1492 Slings

Many procurement issues arise because buyers:

- Assume “synthetic sling” automatically means EN1492 compliant

- Do not request test certificates

- Ignore lifting method load reductions

- Buy based on price without verifying labeling and traceability

Avoiding these mistakes can significantly reduce safety risks and hidden costs.

How We Manufacture EN1492-Compliant Webbing Slings

At Aparejo LDR, all EN1492 webbing slings are manufactured with strict quality control, incluido:

- Raw material tensile testing

- Proof load and breaking load tests

- Visual inspection and dimensional checks

- Clear labeling and batch traceability

Each shipment can be supplied with test reports and certificates upon request, ensuring full compliance with EN1492 requirements.

Final Checklist for Buyers

Before placing an order, buyers should confirm:

- ✔ EN1492-1 or EN1492-2 compliance

- ✔ Correct WLL for lifting method

- ✔ Proper color coding

- ✔ Clear, durable labeling

- ✔ Test certificates availability

Get EN1492 Certified Webbing Slings

If you are sourcing EN1492-compliant webbing slings or round slings, our team is ready to support your project with reliable products and professional technical advice.

👉 Contact us today to get a quotation or technical consultation.